Application

DACm hybrid fiber optic cable with additional insulated copper conductors is designed for direct burial in soil (including frozen deformated soil), laying through rivers crossings, navigable rivers and deep-water lakes and reservoirs, bayous, ducts, conduits, collectors, tunnels, bridges and overpasses, in buildings.

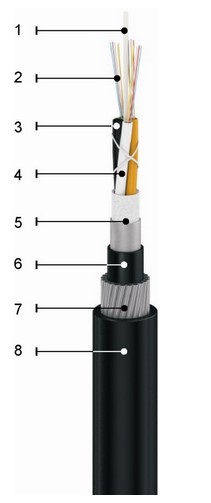

Cable design

- Central strength member – GRP rod.

- Optical fibers of different colors.

- Filler.

- PBT tube filled by hydrophobic compound or insulated copper wires.

- Waterblocking aluminum tape with polymer coating.

- Inner PE sheath.

- Galvanized steel wire armoring, including hight-strength wires with tensile load no less than 1670 MPa.

- Outer PE sheath

Armouring free space is filled with waterblocking compound.

Specifications

- Fiber count – up to 384;

- Copper conductors count – from 1 to 11;

- Static tensile strength – from 7,0 kN to 150,0 kN;*

- Crush resistance – from 0,4 kN/cm to 1,0 kN/cm;*

- Impact resistance – 30 J;

- Allowed bending radius – from 260 mm to 575 mm;

- Excessive hydrostatic pressure resistance – at least 2 MPa;

- Cable diameter – from 13,0 mm to 28,8 mm;

- Cable weight – from 275 kg/km to 1330 kg/km;

- Outer PE sheath insulation resistance (circuit “armor – land (water)”) – 4000 MOm*km;

- Copper conductor diameter – from 0.4 mm to 2.8 mm;*

- Cable length on a drum – up to 4 km.

Diameter, weight and bending radius are reference values.

* – customer can choose values in ranges provided