Application

OPL optical fiber cable is designed for laying in ducts, conduits, collectors, tunnels, on bridges and overpasses, buildings,in case of danger of damage by rodents, in case of increased requirements for protection against water penetration.

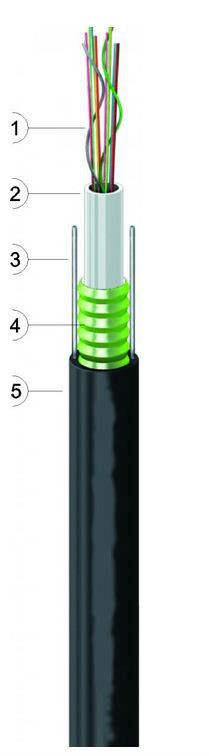

Cable design

- Central polymer tube filled by waterblocking compound.

- Optical fibers (or fiber bundles) of different colors.

- Galvanized steel wire.

- Corrugated steel tape with polymer coating.

- Outer PE sheath.

Specifications

- Fiber count – up to 64;

- Static tensile strength – from 1,5 kN to 3,0 kN;*

- Crush resistance – from 0,4 kN/cm to 0,7 kN/cm;*

- Impact resistance – 30 J;

- Allowed bending radius – from 150 mm to 190 mm;

- Cable diameter – from 7,5 mm to 9,5 mm;

- Cable weight – from 70 kg/km to 105 kg/km;

- Outer PE sheath insulation resistance (circuit “armor – land (water)”) – 4000 MOm*km;

- Cable length on a drum – up to 12 km.

Diameter, weight and bending radius are reference values.

At the demand of the customer, for cables used in buildings, ducts, conduits and tunnels, outer sheath may be made of flame retardant polymer composition not containing halogen (LSZH).

* – customer can choose values in ranges provided